NX CAD (formerly known as Unigraphics) is a comprehensive suite of CAD tools used for product design, engineering, and manufacturing. It’s widely used in industries like aerospace, automotive, machinery, and consumer goods due to its advanced capabilities in 3D modeling, simulation, and design for manufacturing (DFM).

If you’re interested in learning NX CAD, here’s an overview of what a typical NX CAD course might cover:

Typical NX CAD Course Outline:

Introduction to NX CAD

Getting familiar with the NX interface and workspace

Setting up preferences and customizing the interface

Overview of different NX modules: Part Design, Sheet Metal, Assembly, Drafting, Simulation, etc.

Basic Part Modeling

Creating 2D sketches and converting them into 3D parts

Using NX’s parametric modeling tools (extrude, revolve, loft, etc.)

Introduction to 3D features like pads, pockets, holes, sweeps, and lofts

Working with constraints and relationships (geometric and dimensional constraints)

Advanced Part Design

Multi-body modeling and advanced 3D design techniques

Surface modeling (freeform surfaces, boundary modeling, etc.)

Parametric design and working with variables and expressions

Handling complex features like drafts, fillets, and chamfers

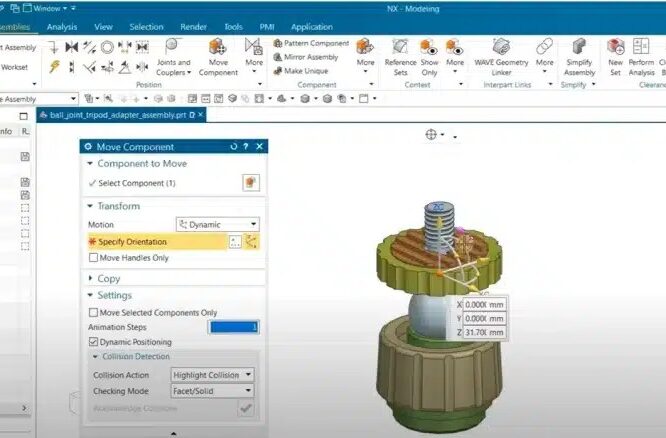

Assembly Design

Creating assemblies from parts

Using mates and constraints to define relationships between components

Working with large assemblies and managing top-down design

Assembly structure, part hierarchy, and working with sub-assemblies

Sheet Metal Design

Creating sheet metal parts (flanges, bends, cutouts, etc.)

Converting 3D parts into sheet metal designs and generating flat patterns

Advanced features like bend tables, unfolding, and flange bends

Drafting and Technical Documentation

Creating 2D drawings from 3D models

Adding dimensions, annotations, and notes

Generating views (section, detail, auxiliary) and bill of materials (BOM)

Understanding drawing standards (ISO, ANSI, etc.)

Advanced Modeling Techniques

Working with sheet metal and composite parts

Creating flexible assemblies and motion studies

Advanced surface modeling for complex geometries (like body panels in automotive design)

Multi-body modeling and handling complex interdependencies

Simulation and Analysis

Performing basic structural analysis (stress, strain, etc.)

Kinematic simulation for analyzing movement within assemblies

Motion and dynamic analysis of moving parts in assemblies

Thermal analysis and evaluating designs under different loads

Design for Manufacturing (DFM) and CAM Integration

Optimizing designs for manufacturability (DFM principles)

Integration with NX CAM for creating machining instructions from the CAD model

Understanding and applying tolerance analysis and GD&T (Geometric Dimensioning and Tolerancing)

Product Lifecycle Management (PLM)

Working with Teamcenter (NX’s PLM system) for managing design data

Version control, data collaboration, and design revision management

Integration with other enterprise tools for end-to-end product lifecycle management

Project Work and Practical Applications

Hands-on projects that allow you to apply NX CAD tools to real-world design challenges

Creating a portfolio of designs, assemblies, and technical documentation

Working in groups or individually on design projects (product development, automotive parts, etc.)

Why Learn NX CAD?

Industry Leadership: NX is one of the leading CAD tools in industries like aerospace, automotive, and industrial machinery. Companies like Boeing, General Motors, and Siemens use NX for their engineering needs.

Integrated Environment: NX integrates CAD, CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering) into a single platform, making it ideal for product development from concept to production.

Advanced Capabilities: NX offers advanced capabilities like multi-body modeling, generative design, and additive manufacturing.

Collaboration & PLM: It has built-in tools for collaboration and integrates with PLM systems, ensuring smooth workflows in large-scale product development projects.

NX CAD Course Benefits at Skillverse:

Hands-On Training: A Skillverse NX course would likely include practical sessions where you create actual parts and assemblies using NX CAD, simulating real-world engineering challenges.

Comprehensive Coverage: You’ll learn not just the basics of part design but also advanced topics like sheet metal design, assembly modeling, simulation, and manufacturing.

Industry-Relevant Skills: Skillverse would ensure you’re learning skills that are highly sought after in industries like aerospace, automotive, and machinery.

Certification: Completion of the course would likely offer a certification, which can boost your credentials in the job market.

Why Choose NX CAD?

Versatility: NX is suitable for a wide range of applications, from product design to manufacturing to simulation, making it a great all-in-one tool.

High Demand: Many companies in industries like aerospace, automotive, and defense require proficiency in NX CAD, and learning it can significantly improve your career prospects.

Cutting-Edge Features: NX offers advanced tools for simulation, generative design, and complex part modeling, which are essential for modern product development.

NX CAD at Skillverse:

If Skillverse offers a course in NX CAD, it will likely cover both beginner and advanced topics, depending on your current skill level. The course will be tailored to meet industry standards and best practices, providing you with a robust understanding of how to use NX for design and manufacturing tasks.

If you’re planning to pursue a career in industries that use NX CAD, the course can be a great way to equip yourself with the skills employers are looking for.

Do you have any specific areas within NX CAD you’re interested in, like assembly design, simulation, or sheet metal? Or is there a particular industry you’re aiming for? Let me know, and I can give more tailored advice!